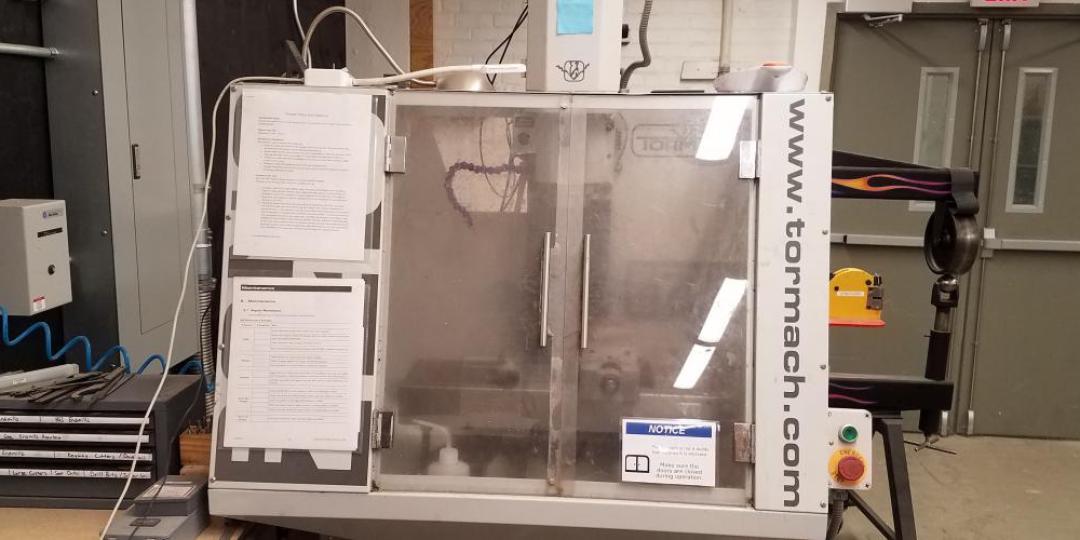

Hands on learning of the fundamentals of safe and practical use of the Tormach PCNC 440 Metal Mill.

This class will teach the basics of CNC milling and machining on the Tormach CNC Mill. Knowledge of CAD/CAM software such as Fusion 360 is recommended but not required.

Students who successfully compete this class will earn the Advanced Metal CNC Badge, allowing ongoing use for members. Students *must* have experience on the Bridgeport Mill prior to taking this class. Badging qualifies if participant is a member. If not a member, please provide proof of experience with a milling machine. Previous attendance at a MakeHaven class for the Bridgeport qualifies.

Class Objectives:

Identify the locations and function of the milling machine's E-stop

Identify and demonstrate proper use of Personal Protective Equipment (PPE)

Identify the location and function of the components on the mill

Required machine maintenance including way oil pump

Learn and understand the differences between manual and CNC milling

Learn the basics of the Tormach PathPilot Interface

Demonstrate cleaning, installing and setting tools

Demonstrate and understand use of the probe

Explain and demonstrate setting and understanding work origins

Learn reasonable feeds & speeds for the machine

Understand basic G-Code and programming

Explain and demonstrate manually writing and modifying G-Code

Preform test cuts in air

Observe a demonstration cut in material to see the effect of various speeds and feeds

Demonstrate posting (exporting) G-Code from CAM software

Demonstrate required clean up after use

Member for

6 years 9 months

MakeHaven Main Space

The main makerspace and connected shops. This is located at 770 Chapel Street. Registered participants should ring the MakeHaven labeled doorbell. They will be directed down a long hallway, and down a set of stairs to our basement workshop.