home

INventors

The perfect place to create prototypes and get feedback on your work, or just engage with a community of people working on the frontiers of technology.

Hobbyists

Connect with others who share your passion. Share the skills you have developed and expand your horizons.

ARTISANS

Experiment with new mediums and push yourself to create something unique. Hone woodworking, sewing or printmaking skills.

The tools to make anything!

Wood shop

Full workshop with all the equipment including: table saw, band-saw, CNC, lathe, planer and hand tools.

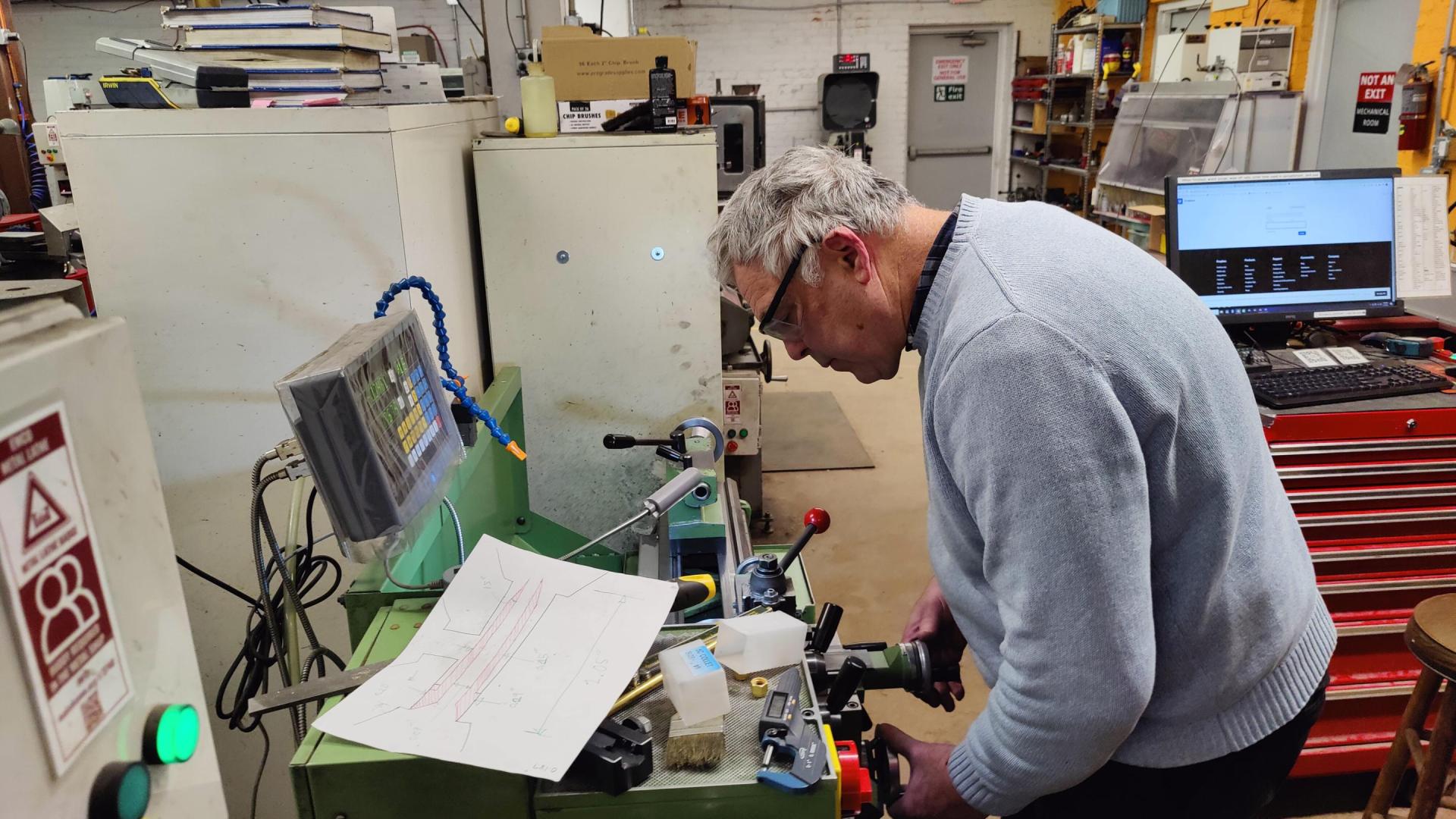

Metal SHop

Full metal working shop with saws, vertical mills, CNC machine, waterjet cutter, lathes, welding, jewelry making and blacksmithing.

Textiles & Sewing

Sewing machines, quilting machine, knitting machine, computerized embroidery and an area to layout and cut large fabrics.

Ceramics & Plastics

Pottery wheels and kiln. Pressure pot and vacuum chamber to support casting. Vacuum former, injection molder, resin 3d printer, shredder and compression oven for plastics.

Digital Fabrication

Many 3d printers, laser cutters, CNC milling machines, access to design software and more.

Electronics & Radio

Electronics workbench with oscilloscopes, soldering station, reflow oven, and ham radio with antennas on the roof.

Media & Printmaking

Presses for woodblock, screen printing capabilities and a media room built for podcasting and product photography.

HOME BREWING & BIO

MA computerized home brewing system and Community Bio Lab capable of work with DNA and growing biomaterials.

We will email you about upcoming events and workshops.